Kontane Logistics OFFERS

Tire and wheel assembly and modular just-in-sequence automotive sub-assembly solutions.

Let Kontane’s tire and wheel assembly group design a custom solution around your OEM’s requirements. Whether it is a heavy duty Class-8 truck tire or an automotive mini-spare, we handle it all. We provide all types of line sequenced sub-assembly solutions for the automotive industry.

Automotive Tire and Wheel Assembly

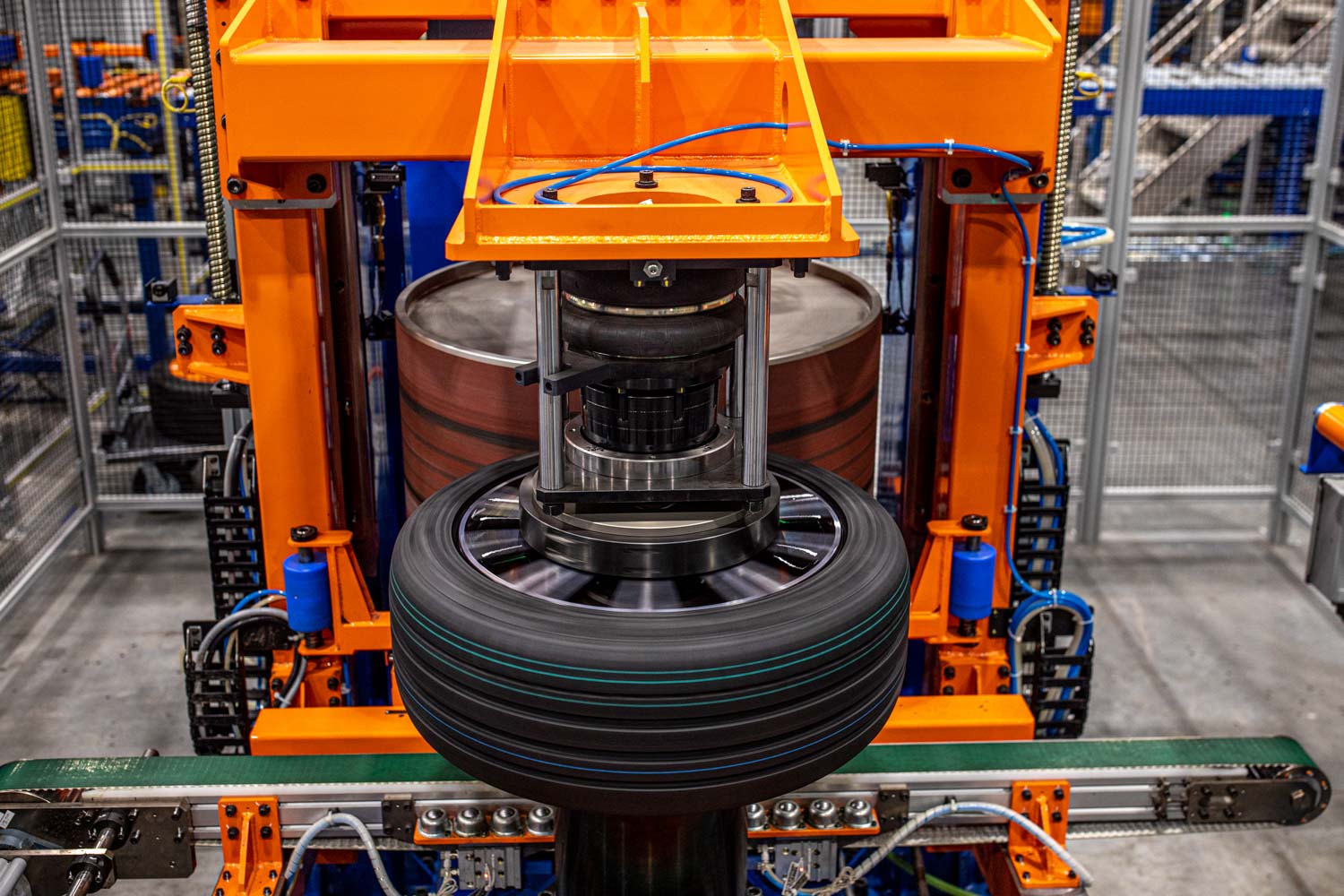

Kontane Logistics supplies tire and wheel assembly services to the world’s most respected automotive OEM’s. Our well-trained team meets or exceeds all the rigorous quality requirements the automotive industry demands. We can build and ship just in sequence (JIS) or batch build to your demand. Our tire and wheel assembly services include value stem and tire pressure monitoring system installation, robotic tire and wheel soaping, robotic tire and wheel mounting, match marking, tire inflation, bead optimization, low speed uniformity check, balancing and robotic weight apply and audit balancing. We install vision systems on our line to ensure the accuracy of deliveries. We only use the most technologically advanced tire and wheel assembly equipment to maximize quality and efficiency.

Medium – Heavy Duty Truck Tire and Wheel Assembly

Kontane has been performing tire and wheel assembly for heavy-duty and medium-duty truck manufacturers since 2010. The wide variation of sizes and part combinations require advance planning and assembly techniques. We perform value stem installation, TMPS install, mounting, match marking, inflating, and balancing. We also provide custom wheel painting when required.

Tire and Wheel Uniformity & Balancing

To ensure the optimal ride for the driver, tire and wheel assemblies need balancing and low radial and lateral force readings (uniformity). We will follow the OEM’s specifications for uniformity and balancing runout to ensure all assemblies are within spec. Our inline balancers and robotic weight apply station produces a reject rate of less than 1% first time through. This results in a better balance, improved cycle times, reduced scrap and lower cost.

Quality and Error Proofing

We install poka-yoke techniques and processes throughout all our tire lines to ensure quality assemblies are consistently delivered to our customers. We use a combination of vision systems, pick to light systems, barcode scanning and visual inspection. Our truck tire and wheel assembly group has won the Masters of Quality Award for a major truck OEM for 8 years in a row, an award that only goes to the top 3% of their supply base.

Tier 1 Services

Kontane Logistics can act as the Tier 1 to the OEM buy purchasing the tire and wheel inventory from the OEM’s suppliers. Our MRP has all the planning, forecasting, purchasing, assembly, EDI, and financial modules to enable this process. We can customize the system to fit your parameters. This reduces the inventory carrying costs for the OEM. It also eliminates the need for the OEM to dedicate valuable resources for inbound logistics planning of the supply chain.

Modular Assembly

Kontane has a long history of providing modular assembly to the truck and automotive industry. We assemble just in time, just in sequence. By performing final assembly close to the OEM, the suppliers can reduce transportation costs, reduce on hand inventory expenses, and increase flexibility to the customers ever changing demands. Our team will work with the supplier to develop build requirements, quality goals and KPI’s to ensure the program’s success.